Rack Inspections

If you operate a warehouse or even just one bay of racking, you are obliged by law to inspect the pallet racking at regular intervals. Inspection of work equipment including racking is governed by the Workplace (Health, Safety and Welfare) Regulations of 1992 and the Provision and Use of Work Equipment Regulations (PUWER) of 1998.

Inspections should take place no more than 12 months apart and should be carried out according to SEMA Guidelines No.6 – Guide to the Conduct of Pallet Racking and Shelving Surveys.

It is normal for racking to suffer a certain amount of wear and tear, and regular inspections help you recognise when and which repairs are needed – helping you keep your warehouse and your employees safe.

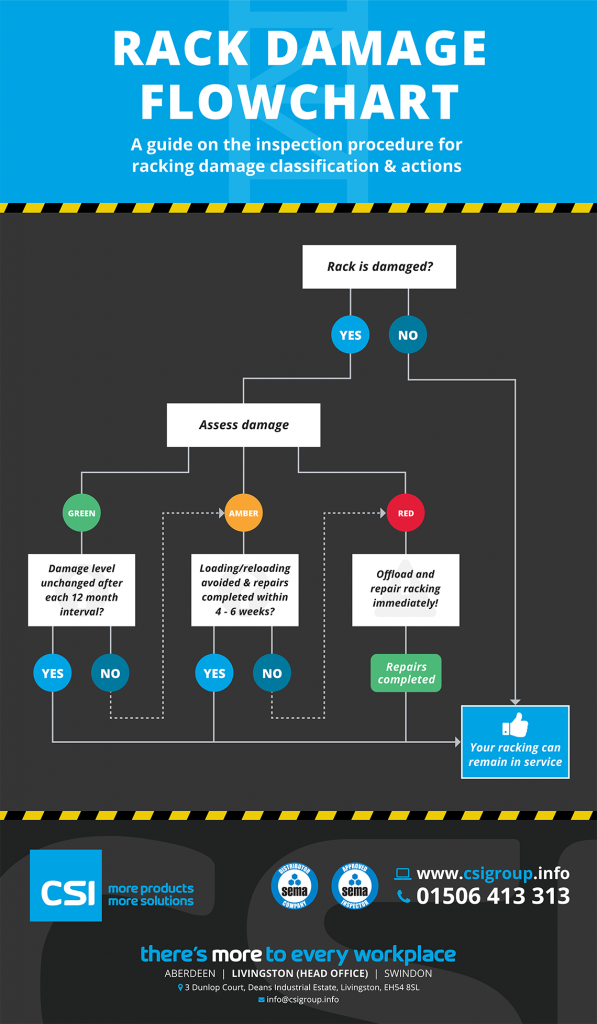

Rack inspections should be carried out by a SEMA approved rack inspector, and the rack inspector will examine all racking closely and classify any damage into three different categories of risk level:

Green

These are items with negligible damage; no remedial action is required and operatives can continue to use the racking as normal. It is important to identify green levels of risk for future reference and monitoring.

Amber

Damage is serious enough to warrant repair, but it does not require the immediate off-loading of the rack. The rack should be off-loaded within 4-6 weeks, and should not be re-used until repair work is carried out.

Red

This indicates severe damage that is well beyond the limitations of the SEMA Code. The racking should be off-loaded immediately and isolated from future use until it has been successfully repaired.

We have created a handy flowchart to help you decide what actions are required based on the level of risk.

Check it out below.

CSI provides SEMA approved pallet and cantilever rack inspections and can also provide training to enable employees to carry out their own rack inspections.

Get in touch with us to book a rack inspection or rack inspection training.