Comprehensive Guide to Oil Storage

Environmentally Friendly Oil Storage

Oil or oil based products (such as petrol, diesel, mineral oil, heating oil, lubricating oil, waste oil, vegetable oil or plant oil) have a huge amount of uses and are used in many domestic, commercial and industrial applications. They also require specialised handling, transportation and storage equipment due to their potential hazard and pollution risks, with strict legislation regarding this. There are thousands of reported incidents of oil pollution in the UK each year, many due to inadequate storage equipment. A leak or spill can have a devastating effect on the water environment by killing animals and insects, preventing the photosynthesis of plants and disrupting the food chain, with a long period of recovery required. It is therefore vitally important that the equipment for oil handling, transport and storage is suitable for purpose. Choosing this equipment will depend on the oil’s application, and where and how it is being stored.

Drum handling equipment like stackers, positioners, tilters and lifters will not only make the handling of oil safer in terms of spillage risks, but also for the staff involved. A full or even half-full drum can be exceptionally heavy so a handling aid can result in an increase in staff productivity, as well as improving their safety. The dimensions and weight of the oil storage units to be moved and the way in which they are to be moved (horizontally or vertically) should be considered when selecting this equipment as well as whether the oil needs to be poured for application and where it will eventually be stored.

When choosing oil storage equipment, the volume of oil to be stored should be carefully considered, as the primary and secondary storage systems must adhere to the requirements of the The Control of Pollution (Oil Storage) (England) Regulations 2001 or the The Water Environment (Oil Storage) (Scotland) Regulations 2006. You should make sure you have the capacity for storage required. IBCs (intermediate bulk containers), drums, safety racks, spill pallets and sump and bund trays will provide safe and secure primary and secondary storage for oil, helping you to minimise the potential hazard and pollution risks and protect the environment.

Your Guide to Secondary Containment Systems

When choosing any secondary containment system you should make sure it fits your requirements under the relevant regulations as to the volume of product you are storing.

Drum and IBC Storage Units

- External storage units complete with safety sumps to catch spills or leakages

- Roof and doors keep rainwater off drums or IBCs as well as integrated sump

- Fitted with integral locking systems to provide extra security and reduce risk of vandalism

- If used for storing large quantities of flammable liquids minimal separation distance from buildings and boundaries should be adhered to

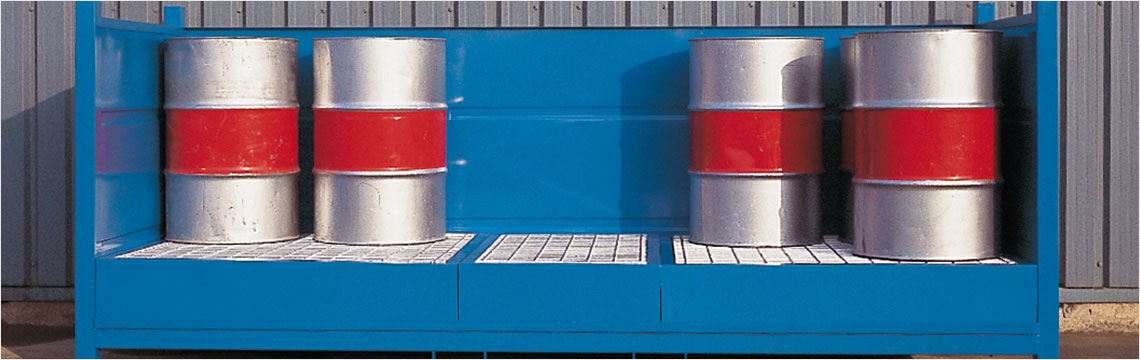

Drum Safety Racks

- Racking made specifically for storing oil drums

- Generally for use indoors

- Easily transported by forklift truck

- Drums are stored off the ground and integrated sump trays provide secondary containment

- Safe dispensing facilities

- When storing drums outlets should be horizontal with each other (at 3 o’clock and 9 o’clock) so that all product will not be lost if leak takes place

- Racks for smaller containment units also available

IBC Stations and Pallets

- Designed for transport by forklift truck

- Allows IBCs to be stored safely and collects any spills or drips when in use

Dispensing Sump Trolley

- For transporting and dispensing single drums or small containers

- Not suitable for use with IBCs

- Ideal for when containers need to be stored near their point of use

Related Articles: